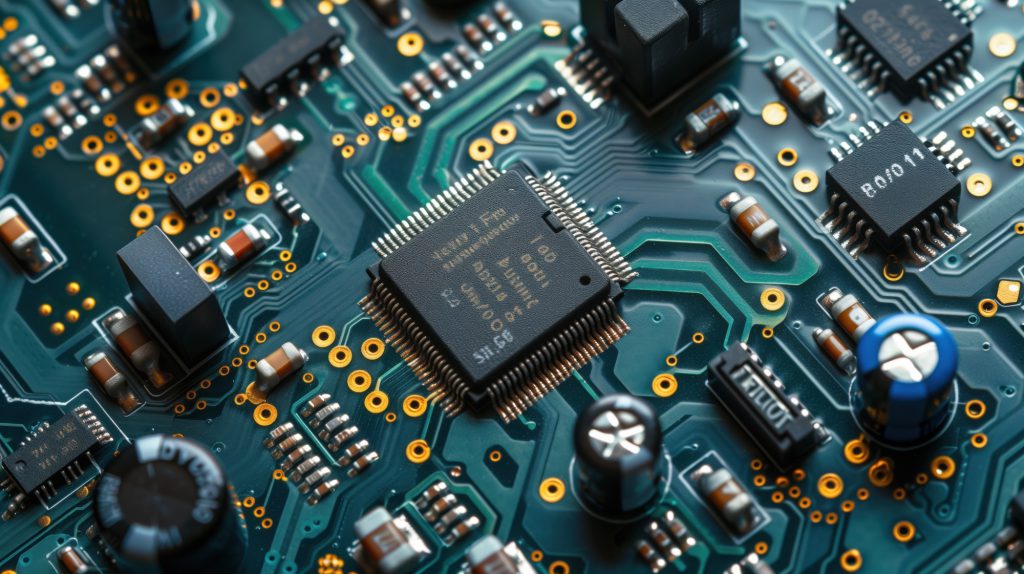

Huawei’s smartphone comeback has become a testament to China’s advancements in semiconductor quality control. Regaining the top spot in the Chinese smartphone market with its Mate series, Huawei’s success is underpinned by innovative chip design and improved domestic manufacturing capabilities. These achievements not only signal the resilience of China’s semiconductor industry but also highlight the critical role of quality control in achieving technological breakthroughs.

Huawei’s Success as a Case Study in Quality Control

Huawei’s ability to return to the forefront of the smartphone market is largely due to its advancements in semiconductor technology and collaboration with domestic foundries. The development of the Kirin chipset demonstrates Huawei’s capacity for innovation, even under global trade restrictions that limited access to foreign technology.

Working with partners like SMIC (Semiconductor Manufacturing International Corporation), Huawei has demonstrated how rigorous quality control processes can enhance the performance and reliability of domestically produced chips. By optimizing designs to match the capabilities of local manufacturers, Huawei has ensured high-quality output while addressing the challenges of limited resources.

The Role of Quality Control in Semiconductor Manufacturing

Semiconductor manufacturing is a precision-driven industry where even microscopic defects can render chips unusable. Quality control advancements have played a pivotal role in improving chip performance, yield rates, and overall reliability.

Chinese manufacturers have integrated sophisticated quality assurance systems into their production lines, leveraging automation and AI to detect defects and refine manufacturing processes. These practices have elevated the consistency of domestic chips, ensuring they meet the demanding standards of modern smartphones.

Overcoming Challenges in China’s Semiconductor Industry

China’s semiconductor industry has faced numerous challenges, including initially low yield rates and a steep technological learning curve. However, focused investments in quality management have allowed manufacturers to overcome these obstacles.

For example, by employing cutting-edge defect detection technologies and fostering collaborations between industry leaders like Huawei and domestic chipmakers, the sector has improved its ability to produce advanced chips at scale. Government support has also been instrumental, with funding directed toward R&D and the establishment of national standards for semiconductor quality control.

Implications for the Global Market

China’s advancements in semiconductor quality control have significant implications for the global market. As domestic manufacturers continue to meet and exceed international standards, China is becoming less reliant on foreign technology while positioning itself as a competitive player in the global supply chain.

Huawei’s success underscores the importance of balancing innovation with robust quality management practices. By showcasing the potential of homegrown solutions, the company has set a benchmark for other manufacturers aiming to achieve technological self-reliance.

Conclusion

Huawei’s smartphone comeback vividly demonstrates the critical role of semiconductor quality control in driving China’s technological progress. With continued investment in quality assurance systems, talent development, and infrastructure, China’s semiconductor industry is poised to maintain its momentum and expand its influence globally. As Huawei’s story illustrates, advancements in quality control are not just about improving products—they are about redefining a nation’s position in the global tech landscape.